CENTROID CNC Retrofit Features and Options.

There are a lot of standard features with the Centroid control, and some of the most popular are listed below.

USB Memory stick for easy file transfer

Built in hard drive for on board file storage

Ethernet LAN connection

Tool Check Program stop and restart at any point

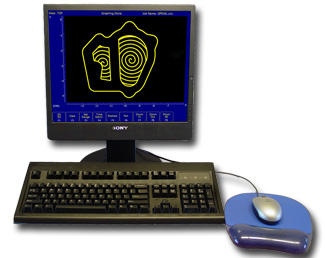

Color Screen, color graphics, run time graphics

Graph G code from any source

Conversational programming and G code!

Built in G code Editor

Part and Tool Setup screens

Runs on Single Phase 110 or 220

Pre-assembled control ready to install.

Accurate Job run time estimation

Software updateable, won’t become outdated

Dedicated operator controls

Threadmilling and Irregular pocket Cleanout.

Many of our retrofit customers have added new functionality to their machines and have expanded their shops machining capabilities by installing a CENTROID CNC control and tailoring it with optional equipment for their specific application. Here are a few examples of the options you can add to your machine once you have a CENTROID.

Digitizing 2D and 3D, Grid , Radial and contouring

Rotary Tables of all sizes

DXF import, turn your CAD drawings into parts

4th and 5th Axis

Tilt Table for Cylinder head machining

Automatic Tool height measurement

Lathe ATC turrets

Offline Conversational programming

Program in the comfort of your office while the machine is out in the shop making chips. CENTROID’s Intercon conversational part programming software is available for your desktop PC. Fast and easy Intercon gets the job done! Import DXF files and turn them into parts, countouring, irregular pocket cleanout, tons of canned cycles, threadmilling, repeats, bolt hole circles, math help and much more. Easy to learn yet a powerful part programming system.

See these features and more in action…Click here to go to the Centroid website for your free DVD video!

CENTROID CNC controls a CNC Controller for Milling Machines,Lathes and Routers, new and retrofit applications.

2016 Centroid CNC control console is packed with CNC Features.

– Touch Screen 15″ LCD Color Display

– Windows Operating System

– Fast state-of-the-art CNC PC

– Solid State Hard Drive

– USB, WiFi, Ethernet LAN

– Dedicated Operator Control Panel

– MPG and Probe Connections

– Thin and Strong only 2.88″ thick

– Uses standard USB keyboards

– Over Internet Support Connection

– G&M Code and Conversational programming!

– Many Standard CNC Software Features

– Made in USA

– Easy Future Software Upgrades

– AC or DC servos

– Up to 8 axis Control

– Add on Advanced capabilities when you need them

– Plug and Play Expandable PLC and Analog I/O

for large complex machines

– Skype video and messaging

– Mill or Lathe Configurations

– Articulating Arm Mount or Adjustable Floor Stand

– OEM, Pro Install or DIY CNC

– Upgrades for older Centroid’s and all other CNC’s